Swarms of tiny robotic bees may be soon springing to life from finely machined sheets of material in a newly designed manufacturing process that combines popup book simplicity with intricate high-tech origami.

The process brings precision control and speed to a previously painstaking process for fat fingered engineers and opens the door to mass production of all kinds of insect-sized robots and other tiny electromechanical devices.

The manufacturing technique stems from the Robobees project at Harvard University, where electrical engineers are developing swarms of miniature flying robots to do everything from pollinate crops to spy on enemies.

One of the challenges the engineers faced was the time-consuming task of creating a swarm one Monolithic Bee (Mobee) at a time. The error-prone process involved gluing together intricate parts by hand while looking through a microscope.

"Until recently, the manual assembly process was the state of the art in this field," Pratheev Sreetharan, a graduate student working on the project, said in a news release.

He and his colleagues have overcome this with a layering and folding technique that takes human hands out of the actual assembly.

They start with 18 layers of carbon fiber, a plastic film called Kapton, titanium, brass, ceramic, and adhesive sheets that each have a unique laser-cut design. The layers are stacked and aligned using pins and laminated together.

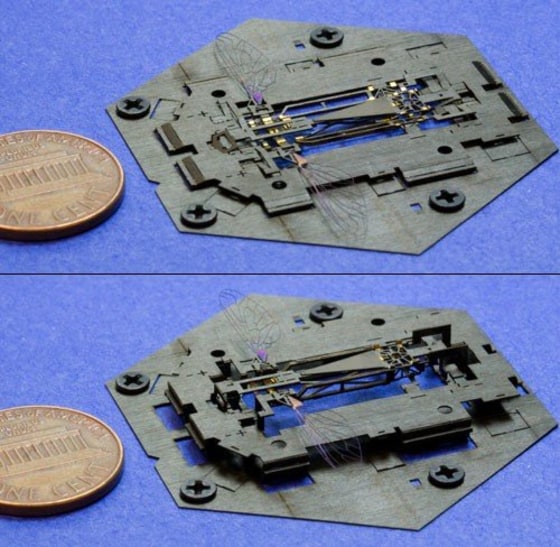

The design incorporates the Mobee layers into an assembly scaffold that uses a system of 137 hinges and folding joints to assemble the insect into a 3-D shape in a single, popup-book-like movement.

Once up, the entire device is dipped in a liquid metal solder that selectively bonds to brass pads, locking the bee together and allowing its removal from the quarter coin-sized assembly scaffold. Once removed, connection to an external power source allows Mobee's wings to flap.

While the technique removes humans and their fat fingers from the assembly process, nimble minds are still required to figure out how all the layers will fit together and fold.

The research team thinks their assembly technique is widely applicable to the fabrication of electromechanical devices with functional parts measured in micrometers and is hoping to commercialize it.

The fabrication technique will be described in the March issue of the Journal of Micromechanics and Microengineering.

More on robotic insects

- Robot spider crawls out of 3-D printer

- Future drones may fly like butterflies

- Biofuel cell may turn cockroaches into cyborgs

- Military developing robot-insect cyborgs

John Roach is a contributing writer for msnbc.com. To learn more about him, check out his website. For more of our Future of Technology series, watch the featured video below.