3-D printing technology is being harnessed to take pesky plastic waste to make human waste disappear via composting toilets.

"You can use the soil that comes out of that for gardening - not crops that grow underground generally, but for something like bananas it is very adequate," Matthew Rogge, an engineering student at the University of Washington, told NBC News.

The concept won the $100,000 top prize earlier this month in the 3D4D Challenge, a contest where teams presented ideas to leverage the fast evolving field of 3-D printing technology to deliver real social benefits in the developing world.

Rogge and colleagues will invest the prize money to form a non-profit organization and collaborate with Oaxaca, Mexico-based Water for Humans to create lightweight composting latrines and rainwater harvesting systems.

"In Oaxaca, they have to carry these from where they are produced up into the mountains to the communities that are going to use them and the trails are so steep they won't even use pack animals," Rogge said.

That's a problem since other composting latrines are concrete, too heavy for people carry on their backs. The 3-D printed ones will be light enough to haul, giving the technology a shot at adoption in the mountain communities.

3-D printers are poised to revolutionize manufacturing. Akin to a traditional inkjet printer, they squirt out liquid material following instructions from a computer. But instead of stopping at one layer of ink, these machines print in three dimensions by putting one layer on top of another.

To do this, traditional ink is replaced with materials that harden with each pass of the nozzle. This can be plastics in the case of trinkets such as a Yoda statue or a model airplane that can fly.

Rogge and his colleagues aim to use waste plastics such as milk jugs and soda bottles as the source material for their printer. "It basically just melts the plastic down and squirts it out a ... little hole," he explained.

In addition to lightweight latrines, the team will use the printer to make parts for rainwater collection systems that will be more robust than the typical cobbled-together-from-spare-plumbing-parts versions found in the developing world.

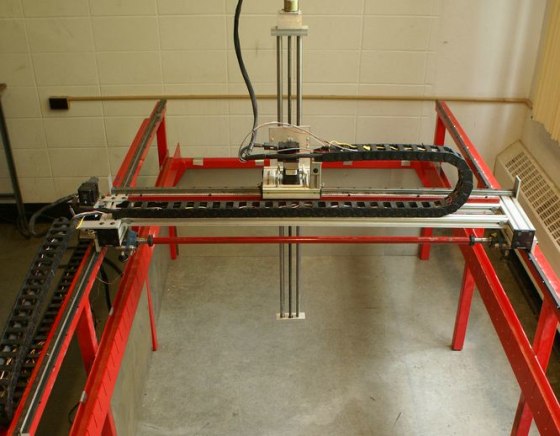

As a proof-of-concept, earlier this year the team printed a life-size boat from more than 250 plastic milk jugs using their custom built Big Red printer. The entered the boat in a milk jug derby and took second place.

The concept for the toilet grew out of Rogge’s work in the Peace Corps building water and irrigation systems in Ghana, Panama and Bolivia. Building custom parts in these low-resources countries, he said, was frustrating.

When he learned about 3-D printing technology, he decided to go back to school to learn how to use it. Winning the $100,000 prize, he said, is like a dream come true.

“I feel lucky to have the chance to start making our ideas into reality,” he said in a news release. “There is a great potential here to improve people’s quality of life while taking plastic out of the waste stream.”

John Roach is a contributing writer for NBC News Digital. To learn more about him, check out his website. For more of our Future of Technology series, watch the featured video below.